What You Need to Know:

They are commonly referred to as low-acid-canned-foods (or "LACF") even though they may not be packaged in a can.

Low Acid Foods in Hermetically Sealed Containers are by definition (1) shelf stable, (2) heat-treated (3) have a pH of >4.6 and (4) a water activity of 0.85

Examples of Low Acid Foods in Hermetically Sealed Containers include: shelf-stable milk in pouches, canned beans, vegetable broth in a pouch.

There are 2 primary methods for processing LACF: Using a Retort (pressuring cooker) and Aseptic Processing (a sterile packaging process)

They are regulated in 21 CFR Part 113: Thermally Processed Low Acid Foods Packaged in Hermetically Sealed Containers

Key Terms

Low Acid Foods have a pH of >4.6 and a water activity of >0.85

Hermetically Sealed Container is packaging which prevents the entry of microorganisms and maintains the commercial sterility of the contents.

Commercial Sterility means there is zero microbiological activity (including bacteria, spores or anything that could reproduce under shelf-stable conditions

LACF ("Low-Acid-Canned-Food"): This term is used interchangeably with "Low Acid Foods Packaged in Hermetically Sealed Containers". It may apply to foods packaged in containers other than cans (i.e. flexible pouches or jars) which is why the term "hermetically sealed container" is used.

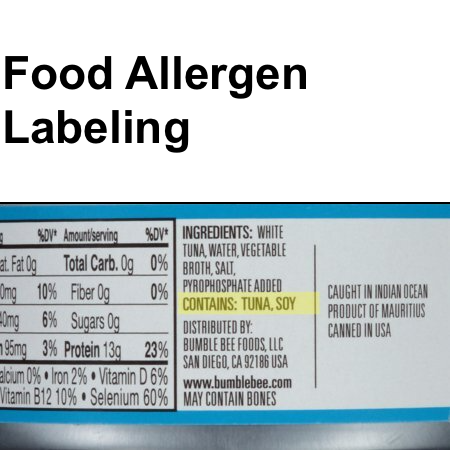

Examples of Low Acid Canned Foods:

This list only includes food products that would be governed under the FDA. Foods that fit the definition of LACF and contain >2% meat content are governed under the USDA.

shelf-stable milk (commonly packaged in pouches)

Canned tuna

Canned black beans

Canned corn

Canned mushrooms

Canned Cauliflower

Shelf-stable vegetable broth

Does Part 113 Apply to your food product?

Is my product a Low-Acid-Canned-Food (LACF)?

Even if your product is not "canned", it may fall under the regulation of Part 113. Use the flow (above) to the right to determine whether your product is considered a LACF (aka "low acid food in a hermetically sealed container")

Requirements for Producers of LACF

Personnel

The operators of a processing system that produces LACF must have attended an FDA approved course that instructs on how to safely process these foods. An example of an approved course is "The Better Process Control School" which is offered online or in person.

Equipment and Procedures

The bulk of regulation under Part 113 relates to the requirements for thermal processing and aseptic processing.

Methods for Processing LACF

The two primary methods for processing low-acid-canned-foods are retort and aseptic processing.

Retort

A retort is a large pressure cooker. Sealed containers of food (typically cans, jars, or pouches) are loaded into the retort and heated using steam and pressure. This thermal treatment kills all of the microbiological activity in the containers.

In a retort process, products are treated after they are packaged and sealed.

The use of high pressure allows the retort to achieve temperatures above boiling, which allows for products to rapidly achieve sterility.

Examples of Foods Processed by Retort: Canned beans, canned vegetables, canned soup, canned tuna

Aseptic Processes

In an aseptic process, the food products are heat processed prior to packaging. Since there is a risk that the packaging or food may become contaminated in the packaging step, the entire process takes place under sterile conditions (hence the term aseptic).

Aseptic manufacturing requires tremendous control to maintain a sterile environment during processing. The machinery to perform this type of process is typically very expensive.

Examples of Foods Processed by Aseptic Process: Shelf-Stable Milk, juice boxes

Exemptions for Producers of Low Acid Canned Foods (LACF)

Processors who operate under Part 113 are exempt from the following requirements:

Subpart C (Hazard Analysis and Risk Based Preventive Controls)

Subpart G Supply Chain Controls

However, this exemption only applies in regards to microbiological hazards regulated under Part 113. Simply -- if the food processor identifies chemical or physical hazards in their production process, they must address those hazards as they are outlined in Subpart C.

Additionally, if the processor identifies a hazard that requires a supplier-applied preventive control, then the processor would have to conduct supplier verification activities as described in Subpart G.

FAQ

Are fermented foods regulated under Part 113?

If the fermented food has a pH of >4.6 and a water activity > 0.85, then it is considered a "low-acid-canned food" (LACF) and is regulated under Part 113.

If the fermented food has a pH of <4.6 then it is not regulated as a Low-Acid-Canned-Food (Part 113) OR an acidified food (Part 114).

Are Alcoholic Beverages Regulated Under Part 113?

No. Alcoholic beverages are not regulated under Part 113 (Low Acid Foods in Hermetically Sealed Containers) or Part 114 (Acidified Foods).

Sources

21 CFR Part 113 -- Thermally Processed Low Acid Foods Packaged in Hermetically Sealed Containers